Circlips

Circlips: Essential Retaining Rings for Mechanical Applications

What Are Circlips?

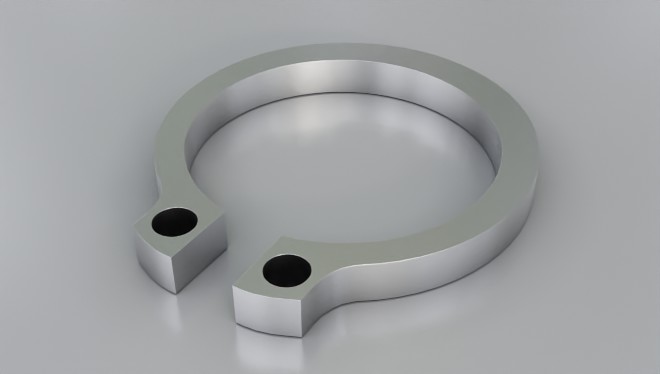

Circlips, also known as retaining rings or snap rings, are a type of fastener used to secure components on a shaft or in a housing/bore when installed in a groove. They prevent lateral movement and are crucial in various mechanical assemblies. Circlips are commonly made from spring steel or other metal alloys, providing flexibility and strength.

Types of Circlips

There are two primary types of circlips:

- Internal Circlips: These are installed into a groove inside a bore or housing to prevent components from sliding out.

- External Circlips: These fit into a groove on a shaft and prevent components from sliding off the shaft.

Design and Variations

Circlips come in various designs and styles to suit different applications:

- E-clips: These are E-shaped and snap into place on a shaft without needing a groove.

- C-clips: C-shaped clips that are commonly used in automotive and heavy machinery.

- Spiral Retaining Rings: These offer a 360-degree retaining surface without the lugs that protrude from standard circlips.

Materials

Circlips are typically made from:

- Spring Steel: Offers excellent elasticity and strength.

- Stainless Steel: Provides corrosion resistance, suitable for harsh environments.

- Beryllium Copper: Used for its non-magnetic and non-sparking properties.

Applications

Circlips are used in a wide range of applications, including:

- Automotive: Used in gearboxes, differentials, and wheel hubs.

- Aerospace: Essential in various components due to their reliability and strength.

- Industrial Machinery: Secures bearings, gears, and other critical components.

- Consumer Electronics: Keeps small components in place within devices.

Advantages of Circlips

- Efficiency: Quick and easy to install and remove.

- Cost-Effective: Inexpensive compared to other fastening methods.

- Space-Saving: Requires minimal space within assemblies.

- Secure: Provides reliable and secure retention of components.

Installation and Removal

Circlips require specific tools for installation and removal:

- Circlip Pliers: These come in internal and external versions, designed to fit into the holes or notches of the circlip for easy manipulation.

- Snap Ring Pliers: Used for installing and removing snap rings or E-clips.

Standards and Specifications

Circlips are manufactured according to various international standards to ensure compatibility and performance:

- DIN 471: Standard for external circlips.

- DIN 472: Standard for internal circlips.

- ISO 9001: Ensures quality management systems are in place during manufacturing.

Choosing the Right Circlip

When selecting a circlip, consider the following:

- Size: Match the circlip to the shaft or bore diameter.

- Material: Choose a material that suits the environmental conditions and application.

- Type: Decide between internal or external circlips based on the component design.

Conclusion

Circlips are versatile and reliable fastening components essential for various mechanical applications. Their ability to secure components efficiently and cost-effectively makes them a preferred choice in many industries. Whether you need to retain parts on a shaft or within a housing, circlips offer a dependable solution.