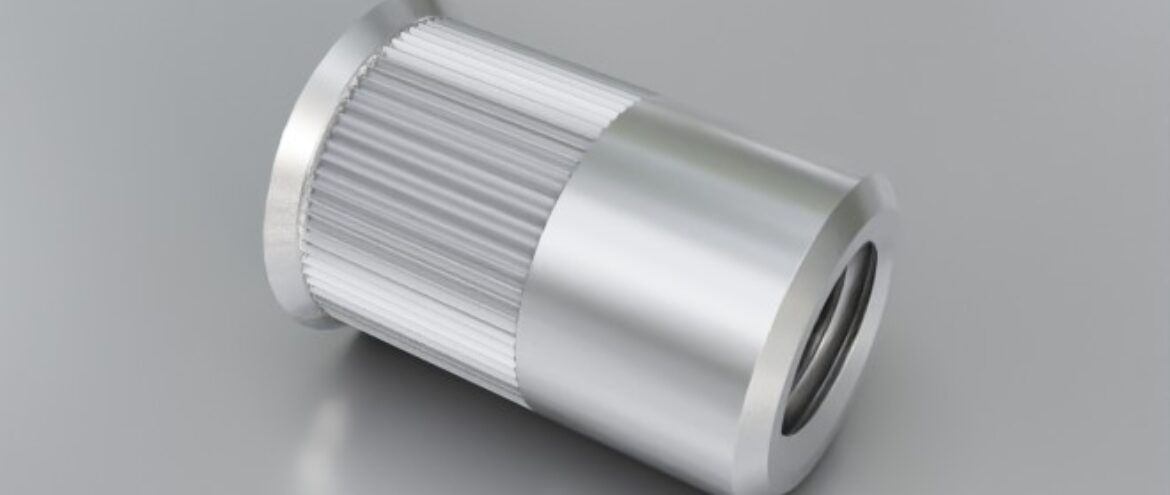

Rivet Bushes

Rivet bushes, also known as threaded inserts or rivet nuts, are fasteners used to create strong and reusable threads in thin materials. They are typically made of metal and are designed to be installed into a pre-drilled hole, providing a threaded insert for screws or bolts. Here’s an overview of rivet bushes, including their types, applications, and installation methods:

Types of Rivet Bushes

- Blind Rivet Nuts (Blind Rivet Bushes)

- Description: Can be installed from one side of the workpiece.

- Applications: Used where access to the backside of the material is limited or not possible.

- Materials: Typically made from aluminum, steel, or stainless steel.

- Self-clinching Nuts

- Description: Installed by pressing into a hole in the sheet metal, creating a flush and permanent installation.

- Applications: Ideal for use in sheet metal fabrication where a strong, permanent thread is needed.

- Materials: Commonly made from hardened steel or stainless steel.

- Threaded Inserts for Plastics

- Description: Specifically designed to be installed in plastic components.

- Applications: Used to provide durable threads in plastic parts, often found in electronics and consumer products.

- Materials: Made from brass or stainless steel.

Applications of Rivet Bushes

- Automotive Industry

- Used for mounting components where only one side of the panel is accessible.

- Provides strong and durable threads in vehicle body panels and other thin-walled structures.

- Aerospace Industry

- Utilized in aircraft manufacturing for fastening components with thin-walled structures.

- Ensures secure and reliable threading in high-vibration environments.

- Electronics and Electrical Enclosures

- Provides strong threads in thin-walled enclosures for mounting circuit boards, connectors, and other components.

- Ensures reliable grounding and secure connections.

- Sheet Metal Fabrication

- Used in fabricating metal enclosures, panels, and other structures where traditional nuts and bolts are not feasible.

- Provides a flush and secure threaded solution.

- Consumer Products

- Employed in products like furniture, appliances, and sports equipment where strong and durable threads are needed in plastic or thin metal parts.

Installation Methods

- Manual Installation

- Tools: Hand tools such as a rivet nut tool or a specialized installation tool.

- Process: Insert the rivet bush into the pre-drilled hole and use the tool to expand and secure it in place.

- Hydraulic or Pneumatic Installation

- Tools: Hydraulic or pneumatic rivet nut setters.

- Process: Used for high-volume production settings where speed and consistency are critical. The tool applies pressure to secure the rivet bush in place quickly and efficiently.

- Press Installation (for Self-clinching Nuts)

- Tools: Mechanical or hydraulic press.

- Process: The rivet bush is pressed into the material, displacing the material around the hole and creating a flush, secure installation.

Advantages of Using Rivet Bushes

- Versatility: Suitable for a wide range of materials, including metals, plastics, and composites.

- Strength: Provides strong and durable threads in thin-walled materials.

- Ease of Installation: Can be installed quickly and efficiently, often from one side of the workpiece.

- Reusable Threads: Allows for multiple assembly and disassembly cycles without damaging the threads.

Summary

Rivet bushes are an essential component in various industries, providing a reliable and efficient way to create strong threads in thin materials. Their versatility, strength, and ease of installation make them a popular choice for applications ranging from automotive and aerospace to electronics and consumer products. Whether for high-volume production or custom fabrication, rivet bushes offer a durable and reusable threading solution.