Blind Rivet Nuts

Blind Rivet Nuts: Versatile Fastening Solutions for Various Applications

What Are Blind Rivet Nuts?

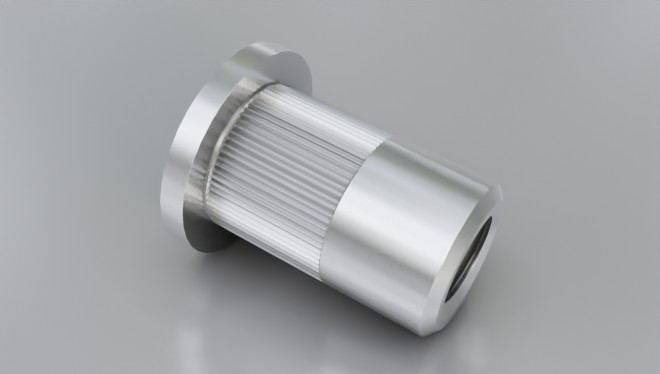

Blind rivet nuts, also known as rivnuts or threaded inserts, are fasteners that provide a strong, reliable method for attaching components to materials where only one side is accessible, hence the term “blind.” They are used to create threaded connections in thin materials like sheet metal, plastic, and composites.

Design and Function

Blind rivet nuts consist of a tubular body with an internal thread and a flange at one end. When installed, the body of the rivet nut is inserted into a pre-drilled hole. Using a special installation tool, the unthreaded portion of the rivet nut is deformed, causing it to expand and grip the reverse side of the material. This creates a secure, load-bearing thread on the accessible side.

Types of Blind Rivet Nuts

There are several types of blind rivet nuts designed for different applications:

- Standard Rivet Nuts: General-purpose rivet nuts used in a variety of applications.

- Hexagonal Rivet Nuts: Provide additional resistance to rotation due to their shape.

- Splined Rivet Nuts: Have splines that bite into the material for extra grip.

- Sealed Rivet Nuts: Designed to provide a watertight seal, preventing fluid and gas leakage.

- Pre-bulbed Rivet Nuts: Pre-formed bulge helps to ensure consistent installation in varying material thicknesses.

Materials

Blind rivet nuts are available in a variety of materials to suit different environments and applications:

- Aluminum: Lightweight and corrosion-resistant, ideal for applications where weight is a concern.

- Steel: Offers high strength and is suitable for most general-purpose applications.

- Stainless Steel: Provides excellent corrosion resistance, ideal for harsh environments.

- Brass: Good for electrical applications due to its conductivity and resistance to corrosion.

Applications

Blind rivet nuts are used across numerous industries and applications, including:

- Automotive: Securing body panels, interior components, and various fixtures.

- Aerospace: Used in airframe assemblies where access is limited.

- Construction: Attaching facades, HVAC systems, and other structural components.

- Electronics: Mounting circuit boards, panels, and other components.

- Manufacturing: Assembly of appliances, machinery, and furniture.

Advantages of Blind Rivet Nuts

- Accessibility: Can be installed from one side of the workpiece.

- Versatility: Suitable for a wide range of materials and thicknesses.

- Strength: Provides a strong, permanent threaded connection.

- Ease of Installation: Quick and simple installation process with the right tools.

- Cost-Effective: Reduces the need for additional hardware and simplifies assembly.

Installation Tools

Proper installation of blind rivet nuts requires specific tools:

- Manual Rivet Nut Tool: Hand-operated tool for low-volume applications.

- Pneumatic Rivet Nut Tool: Air-powered tool for higher-volume or industrial applications.

- Battery-Powered Rivet Nut Tool: Offers mobility and ease of use for medium to high-volume applications.

Choosing the Right Blind Rivet Nut

When selecting blind rivet nuts for your project, consider the following:

- Material Compatibility: Ensure the rivet nut material is compatible with the workpiece to avoid galvanic corrosion.

- Thread Size: Choose the appropriate internal thread size for the required fasteners.

- Grip Range: Select a rivet nut with a grip range suitable for the thickness of the material.

- Environmental Factors: Consider factors such as exposure to moisture, chemicals, or extreme temperatures.

Conclusion

Blind rivet nuts are an essential fastening solution for applications where only one side of the material is accessible. Their versatility, ease of installation, and strong, reliable connections make them ideal for a wide range of industries and applications. Whether you’re working in automotive, aerospace, construction, or electronics, blind rivet nuts offer a practical and efficient fastening solution.