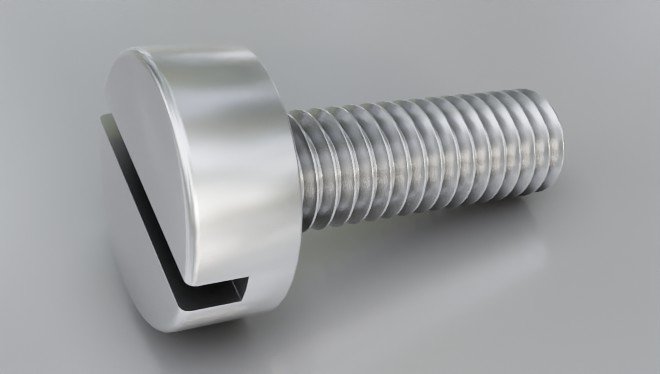

Machine Screw

Machine Screws: Essential Fasteners for Precision Assembly

What Are Machine Screws?

Machine screws are precision fasteners designed for use in machinery and electronic devices. They are typically threaded along their entire length and are used to secure components together, often into a tapped hole or with a corresponding nut. Machine screws are available in various sizes, materials, and head styles to suit different applications and assembly requirements.

Types of Machine Screws

Machine screws come in a variety of head styles, each designed for specific applications and tools:

- Flat Head (Countersunk) Screws: Designed to sit flush with or below the surface of the material for a clean finish.

- Pan Head Screws: Have a slightly rounded top and a flat bearing surface, providing a large contact area.

- Round Head Screws: Feature a domed head for a traditional look and increased strength.

- Oval Head Screws: A combination of flat and rounded heads, offering a decorative finish.

- Socket Head Screws: Feature a cylindrical head and are driven with an Allen key or hex wrench, providing high torque capabilities.

- Phillips Head Screws: Have a cross-shaped drive that prevents over-tightening and cam-out.

Materials

Machine screws are manufactured from various materials to meet different application needs:

- Steel: Commonly used for its strength and affordability. Often coated or plated for corrosion resistance.

- Stainless Steel: Offers excellent corrosion resistance, suitable for environments exposed to moisture or chemicals.

- Brass: Corrosion-resistant and electrically conductive, ideal for electrical applications.

- Aluminum: Lightweight and corrosion-resistant, used in applications where weight is a concern.

- Nylon: Non-conductive and resistant to corrosion, suitable for electrical and light-duty applications.

Thread Types

Machine screws can have different thread types to accommodate specific requirements:

- Unified National Coarse (UNC): Standard thread type used in most applications.

- Unified National Fine (UNF): Provides a tighter thread fit, offering better strength in smaller sizes.

- Metric Threads: Standard thread type used internationally, with sizes specified in millimeters.

Applications

Machine screws are versatile and used across numerous industries:

- Electronics: Securing components in devices, circuit boards, and enclosures.

- Machinery: Assembly of mechanical parts and equipment.

- Automotive: Fastening components in engines, interiors, and body panels.

- Aerospace: Used in airframes, avionics, and other critical components.

- Furniture: Assembly of metal and wood furniture pieces.

Advantages of Machine Screws

- Precision: Fine threads provide precise adjustments and secure fastening.

- Strength: Available in various materials and grades to meet strength requirements.

- Versatility: Suitable for a wide range of applications and materials.

- Reusability: Can be easily removed and reused without damaging the fastener or the material.

- Standardization: Available in standardized sizes and threads, ensuring compatibility and ease of replacement.

Installation and Tools

Machine screws are installed using various tools depending on the head type:

- Screwdrivers: Flathead, Phillips, or Torx screwdrivers for respective screw heads.

- Allen Wrenches: Used for socket head screws.

- Wrenches and Sockets: Used for hex head screws and nuts.

Choosing the Right Machine Screw

When selecting machine screws for your project, consider the following:

- Material Compatibility: Ensure the screw material is compatible with the material being fastened to avoid galvanic corrosion.

- Thread Size: Choose the appropriate thread size for the application and the corresponding tapped hole or nut.

- Length: Select a length that provides adequate engagement without protruding excessively.

- Head Style: Choose a head style that fits the design requirements and tool availability.

- Environmental Conditions: Consider exposure to moisture, chemicals, or temperature extremes when selecting the screw material.

Conclusion

Machine screws are essential fasteners for precise and secure assembly in a wide range of applications. Their versatility, strength, and availability in various materials and sizes make them a preferred choice in industries such as electronics, machinery, automotive, and aerospace. By selecting the appropriate machine screw for your application, you can ensure reliable and durable connections.