Nuts

“Nuts” in the context of fasteners are hardware components with a threaded hole, designed to be used in conjunction with a bolt or a threaded rod to fasten multiple parts together. Here is an overview of nuts, including their types, applications, materials, and installation methods:

Types of Nuts

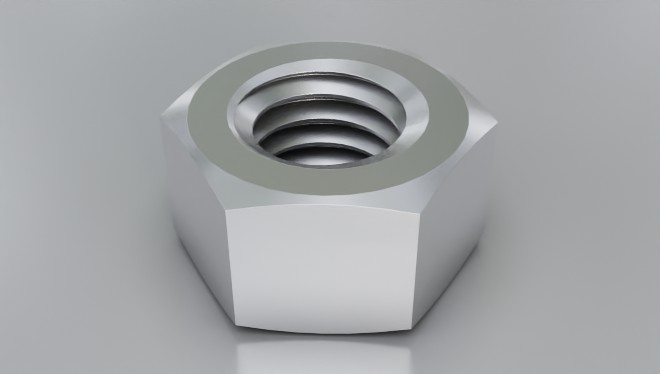

- Hex Nuts

- Description: The most common type, hexagonal in shape.

- Applications: General-purpose fastening for a wide range of applications.

- Variants: Heavy hex nuts, thin nuts, jam nuts.

- Lock Nuts

- Description: Designed to prevent loosening under vibration and torque.

- Applications: Used in applications subject to vibration, such as machinery and automotive.

- Variants: Nylon insert lock nuts (nylock nuts), metal lock nuts, prevailing torque lock nuts.

- Wing Nuts

- Description: Features protruding “wings” for hand tightening.

- Applications: Situations requiring frequent adjustments or hand assembly.

- Materials: Commonly made from steel, stainless steel, or brass.

- Cap Nuts (Acorn Nuts)

- Description: A nut with a domed top, covering the bolt end.

- Applications: Provides a finished appearance and protects the bolt threads.

- Materials: Available in steel, stainless steel, brass, and plastic.

- Square Nuts

- Description: Square-shaped, offering more surface contact.

- Applications: Used in conjunction with flat washers for increased resistance to loosening.

- Variants: Often used in furniture assembly and electrical components.

- T-Nuts (Tee Nuts)

- Description: Has a flange at one end with prongs to grip the material.

- Applications: Common in woodworking to provide a flush, strong, and reusable thread.

- Materials: Typically made from steel or stainless steel.

- Flange Nuts

- Description: Features a built-in washer (flange) to distribute load.

- Applications: Used to spread the load over a larger area and prevent damage to the mating surface.

- Variants: Serrated flange nuts provide additional locking capability.

- Coupling Nuts

- Description: Long nuts used to join two threaded rods.

- Applications: Extending the length of threaded rods or connecting them.

- Materials: Commonly made from steel, stainless steel, and brass.

- Castle Nuts (Slotted Nuts)

- Description: Has slots cut into one end to accommodate a cotter pin.

- Applications: Used in automotive and machinery applications where a secure fastening is critical.

- Materials: Typically made from steel and stainless steel.

Applications of Nuts

- Automotive Industry: Securing components such as wheels, engine parts, and body panels.

- Construction: Used in structural applications, such as steel framing and wood joinery.

- Electronics: Fastening components in enclosures, circuit boards, and mounting hardware.

- Furniture Assembly: Joining parts securely, often with decorative nuts.

- Aerospace: Providing strong and reliable fastening in high-stress environments.

Materials

- Steel: The most common material, offering strength and durability.

- Stainless Steel: Provides corrosion resistance for outdoor and marine applications.

- Brass: Used for its corrosion resistance and decorative appearance.

- Nylon: Lightweight and used for applications where metal-to-metal contact must be avoided.

- Plastic: Used in lightweight, non-load-bearing applications.

Installation Methods

- Hand Tightening

- Tools: Hand tools such as wrenches or sockets.

- Process: Simple and straightforward, suitable for wing nuts and applications where high torque is not required.

- Wrenches and Sockets

- Tools: Open-end wrenches, box wrenches, socket wrenches.

- Process: Provides leverage for tightening and loosening nuts to the desired torque.

- Torque Wrenches

- Tools: Precision tools used to apply a specific torque to a fastener.

- Process: Ensures that nuts are tightened to the manufacturer’s specifications, critical in automotive and aerospace applications.

- Pneumatic and Electric Tools

- Tools: Impact wrenches, nut drivers, power drills with socket adapters.

- Process: Used for high-volume assembly or disassembly, providing speed and consistency.

Summary

Nuts are versatile and essential components in the world of fasteners, used across a wide range of industries and applications. Their various types, materials, and installation methods make them suitable for everything from household repairs to complex machinery and construction projects. Understanding the appropriate type and material of nut for each application ensures a secure and reliable fastening solution.